Ball bearings

Power package with a long service life

Ball bearings are the most frequently used rolling bearing products and are a particularly economical solution. A long service life, high load capacity, guaranteed safety, reliable sealing technology and a particularly low noise level – these are all requirements that a ball bearing should meet. As a specialist for rolling bearing technology, we offer a wide range of ball bearings, including for special, extreme application conditions, and guarantee the best quality in four performance classes at optimum prices and with short delivery times.

Product range

| Series | Description | available in ABEG® performance classes | |||

|---|---|---|---|---|---|

| 60 - 62 - 63 - 64 - 160 - 67 - 68 - 69 | Deep-groove ball bearings in various designs (e.g. ZZ, 2RS, C3 ...) |  |  |  |  |

| 601X to 629 | Miniature deep-groove ball bearings (d < 10 mm) in various designs (e.g. ZZ, 2RS, C3 ...) |  |  |  |  |

| 67 (617) - 68 (618) - 69 (619) - 160 | Thin-section bearings in various designs (e.g. ZZ, 2RS, C3 ...) |  |  |  |  |

| 42 - 43 | Double-row deep-groove ball bearings in open and ZZ |  |  |  | |

| 51 - 52 - 53 | Axial deep-groove ball bearings |  |  |  |  |

| 12 - 13 - 22 - 23 - 112 - 113 | Self-aligning ball bearing with either cylindrical or conical inner ring |  |  |  | |

| 108 ... 135 | Miniature self-aligning ball bearings |  |  | ||

| 70 - 72 - 73 - 718 | Angular contact ball bearings |  |  |  | |

| 38 - 30 - 32 - 33 52 - 53 | Double-row angular contact ball bearings in open, ZZ and 2RS different contact angles available! |  |  |  | |

B718 - B719 - B70 - B72 - B73 HS719 - HS72 |  |  | |||

A history of rolling bearings

Rolling bearings make movement possible. They do this in a wide variety of ways because, when it comes to rolling elements, there are three different designs: balls, rollers and needles. Italian all-round genius Leonardo da Vinci is considered the father of today’s rolling bearing technology: In 1490, he drew the first sketch of a modern ball bearing. Instead of just lubricating the axle and wheel and inserting one into the other, he put a layer of balls between the two components, thereby practically re-inventing the wheel.

However, it was only about 300 years later that this idea started to be used on a massive scale; the ball race was "reinvented" in 1772 and tested in vehicles. Another groundbreaking innovation was the invention of the ball cage, which significantly increased the performance of bearings. Friedrich Fischer’s ball grinding machine enabled perfectly even circular grinding of hardened steel balls, even in large quantities. Fischer’s development laid the foundation for the modern rolling bearing industry.

Over the decades, it was possible to achieve continuous improvements in performance. Findling’s ABEG® method uses these different technology levels in order to offer optimal technical and economical solutions.

Deep-groove ball bearings of electric motor quality

Deep-groove ball bearings from the Xspeed series are specifically designed for use in electric motors and also deliver a convincing performance at high speeds with a particularly long service life..

The Xspeed bearings are designed for high-speed applications. Their use is therefore also recommended in pumps, compressors, fans, rotary encoders or air-conditioning systems. Since running properties play a special role in this segment, Xspeed bearings meet the highest requirements when it comes to the surface quality and profiling of the raceways. They are manufactured in tolerance class P6 with increased precision and radial runout accuracy. The bearing clearance is adapted to the high speeds by tightening the tolerance. This makes it possible to optionally adjust the residual bearing clearance based on the selection of the housing and shaft fit. For a particularly long service life, lubrication and seals were optimized with respect to the requirements of high-speed applications. A special high-purity, viscous and quiet grease with excellent start-up behavior ensures optimum operation at high speeds. The 2RSDD seal variant (axially abutting contact rubber seal inserted into the groove on both sides) reduces the internal heating of the bearing by a whole 10 °C. An even lower-friction (2RW) variant and a non-contact seal variant (LLB) are optionally available.

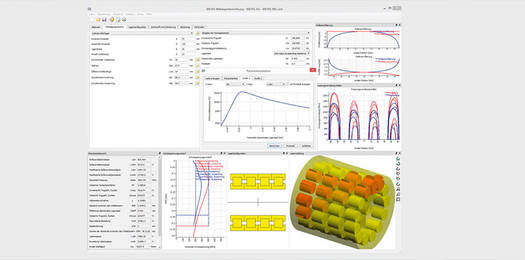

Findling’s rolling bearing technology

As a specialist for rolling bearing technology, we offer a wide range of ball bearings in all ABEG® performance classes, such as single-row or double-row deep-groove or angular contact ball bearings, as well as thrust or radial bearings, magneto bearings, four-point contact bearings or self-aligning ball bearings, which can have a sealed or unsealed design and be made of a variety of materials. Ball bearings are the most frequently used products and are a particularly economical solution.

Technical know-how for ball bearings

Bearing clearance classes C2, CN, C3 and C4

The bearing clearance classes for deep groove ball bearings determine the operating clearance in the interaction of the shaft and housing fit as well as the operating temperature.

Fa - axial load

Fa is the designation for the axial load of a roller bearing.

In the case of deep groove ball bearings, people often ask how high the axial load capacity is. In this case, the rule of thumb is that it is 1/3rd of the radial force.

Noise test by decibels

The noise and vibration test for roller bearings takes place in dB in the noise classes Z, Z1, Z2, Z3 and Z4 according to S0910-1.

Noise test by vibration level

Testing according to BVT-1 is also possible for special requirements. These bearings are classified into V, V1, V2, V3 and V4 according to the tolerance in µm/s.

PN/P0 tolerance class for radial bearings (without tapered roller bearings)

The tolerance class P0 is the standard tolerance class for roller bearings and is usually omitted in the type and order designation for the purpose of abbreviation.